Direct to Garment (DTG) is a newer printing method that gains a lot of popularity in recent years thanks to technology improvement. DTG printing is capable of handling all kinds of design in many colours. This printing method is precise and product high quality results.

DTG printing is more sustainable method for creating packaging because it reduces the waste produced during the printing process. It is more ecological friendly than screen printing. No ink or dye is wasted with DTG printing, there are no plates, blankets, or screens to be washed off eventually ending up in our environment which does damage to our planet.

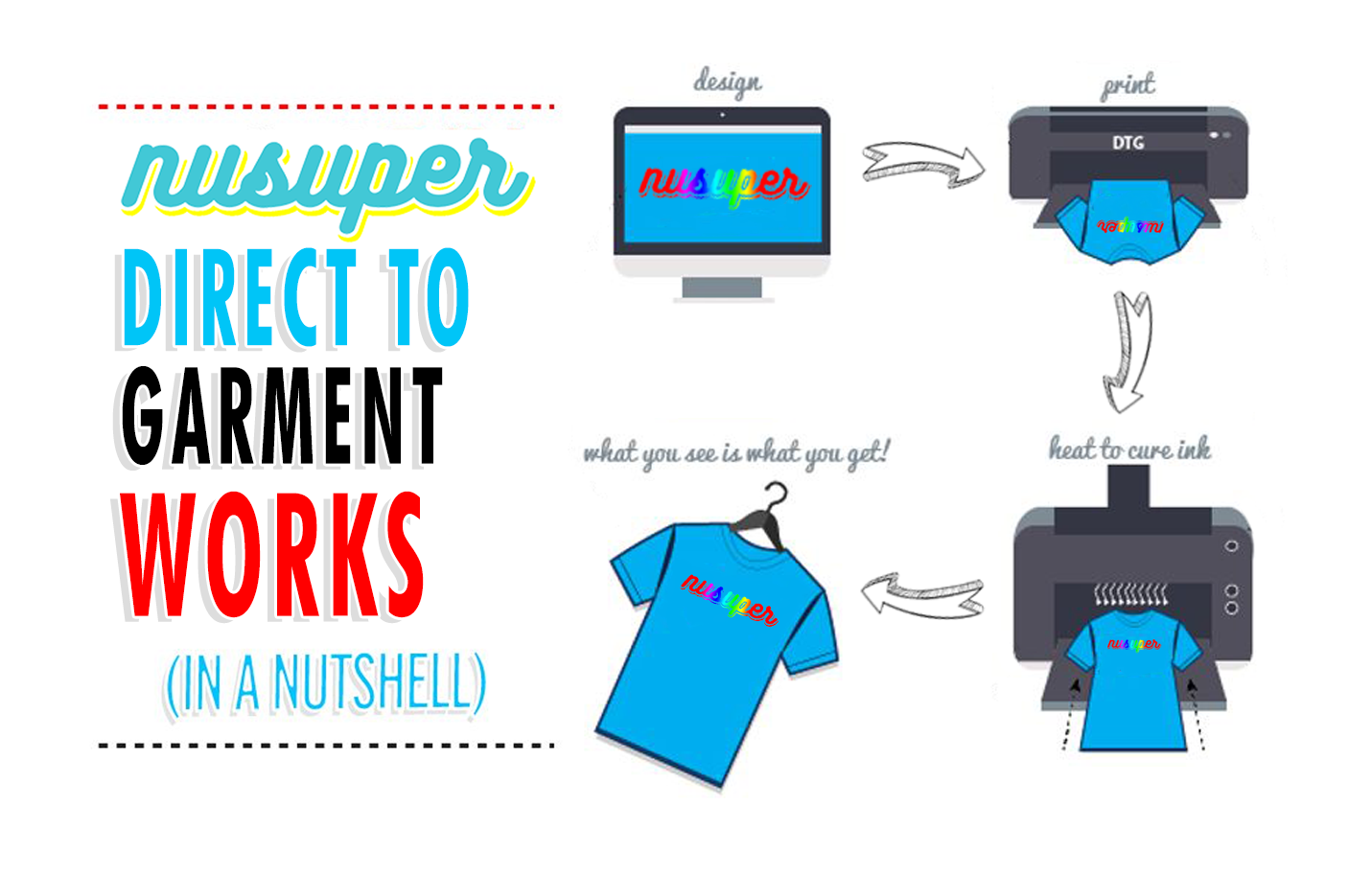

Direct to Garment Printing Process

DTG printing is a process of printing on textile using specialized aqueous ink jet technology. Using platen to hold the garment in a fixed position, and the printer inks are jetted onto the textile by the print head.

End Product

With DTG printing, each product and design coming off the line is usually unique. As compared to screen printing, DTG printing is more durable and, soft to touch because the print is injected into the fibers of the fabric instead of creating a layer on top.

Affordability:

Durability:

Softness of Print: