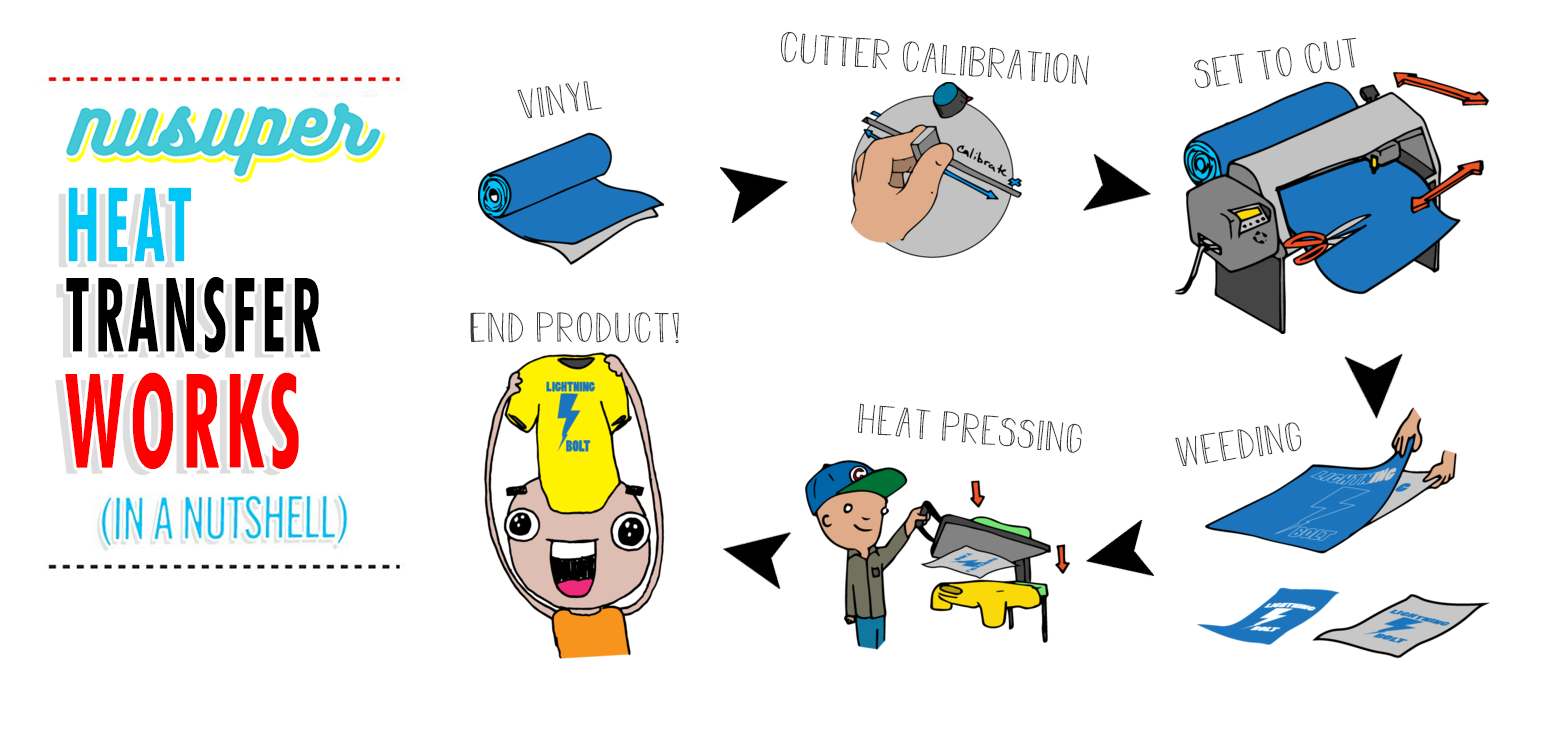

Heat transfer printing is newer decoration method, but it’s comes a long way from the iron-on decals of old. The original applications were commonly applied to soft, vinyl-like materials.This continue to grow with the introduction of digitally produced heat transfer.

There a few different type of inks used in heat transfer printing to achieve different finishes; there is inkjet transfer, dye sublimation transfer, digital applique transfer and vinyl transfer.

Heat Transfer Process

Heat transfer printing is a digital printing method in which material is applied to paper (or some other material) by melting a coating of ribbon so that it stays glued to the material on which the print is applied. It contrasts with direct heat printing, where no ribbon is present in the process.

End Product

Heat transfer is excellence for applying images to various textiles. Heat press t-shirt makers can transfer an image onto a shirt or garment, delivering a durable, wearable and water resistance finished product.

Because of the unique durability of the transferred image, this type of printing is useful in a number of areas and situation. When done well, heat transfer can offer detailed and photo realistic images.

Affordability:

Durability:

Softness of Print: